3200cc Mighty Mouse

Page 2

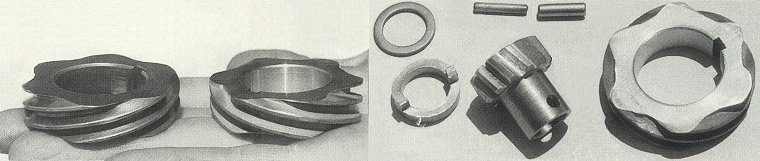

Another thing to consider is that stock Corvair engines were mounted in a rear-engine design and run in a counter-clockwise rotation, which was done for economic purposes to be compatible with existing GM driveline components. GM engineers did this to prevent them from having to design a special transmission and transaxle just for the Corvair. Now, when a Corvair is installed in a buggy with a VW transaxle, whether it be a rear- or mid-engine application, with the engine still turning in its stock rotation it inherently wants to disengage the gears while under power, especially 3rd gear. So, to remedy this problem, manufacturers of aftermarket Corvair engine parts have designed a cam and distributor drive gear set that allows the engine builder to reverse the engine rotation without affecting the oil pump drive. Many people will even say the engine also runs much better with the reverse rotation over the stock configuration, which could possibly be related to the new firing order. Firing order with a reverse rotation gear set is 1-6-3-2-5-4.

The focus of this article is to show what's involved with turning a stock 164 cu. in. engine into a potent 196 cu. in. (3200cc) sand buggy mill. Most of the parts shown in this article can be obtained from Bob Sutcliffe, at SC Performance, in LaVerne, California. As it turned out, Garth Wilson of Wilson Machine Works had one of these engines on order for a customer so we decided to follow along with a camera to document exactly how everything was done.

We'll give you a basic overview of this involved procedure at this time, but the actual specifics are included in the captions beneath the photos. We've done this to allow extra space for the many photos needed to explain how one of these custom built motors is assembled.

Above left, a view of the reverse gear in comparison to stock, and on the right, the entire reverse rotation gear assembly.

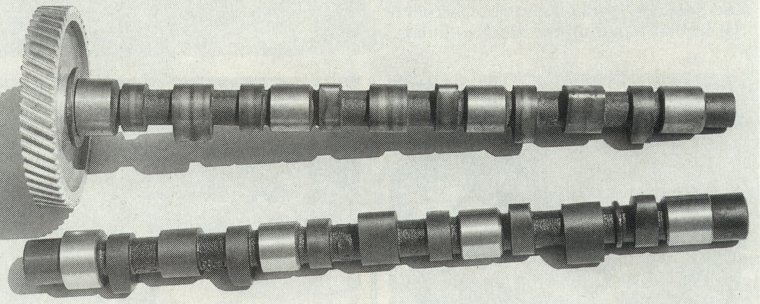

The stock cam is also replaced with WMW performance grind reverse rotation bumpstick, ground at Schneider Cams. The cam with the gear is a stock Corvair unit, but the new cam also gets a billet aluminum cam gear pressed onto it as well, which has an extra dowel pin to retain it in place due to the extra force applied from the motor.

from the reverse gear set and cylinder head modifications mentioned , if you plan to increase the displacement of a Corvair engine, you'll need to use aftermarket VW style pistons and cylinders. Additionally, a few modifications will need to be made to the stock crank and rods.

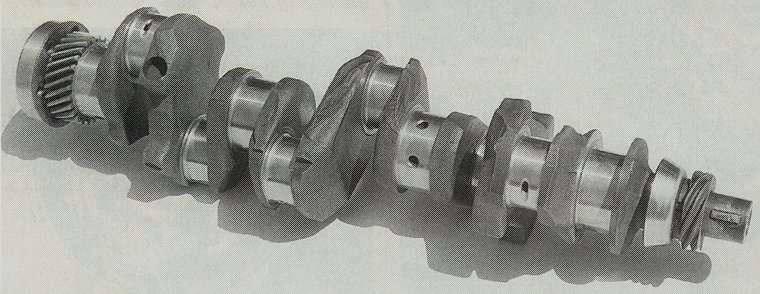

The entire job begins by disassembling the engine and degreasing everything. Then the crank and rods are magnafluxed to check for cracks.